FROM THE IDEA

TO THE FINAL PRODUCT

Mechanical manufacturing

CNC turning

maximum ∅ 430

maximum length 1200mm

on request larger dimensions possible

CNC milling

maximum travel length:

3-axis 2000x800x800mm

5-axis 650x600x600mm

on request larger dimensions possible

Friction stir welding

maximum 3-axis 2000x800x800mm

maximum 4-axis 2000x800x800mm

It can connect different Materials which were know not to be weldable before.

Ultrasonic glass- and ceramic forming

precision grinding maximum 650x500x500mm

Diamond saw

precision cut 0,2-0,4mm

no deformation of material

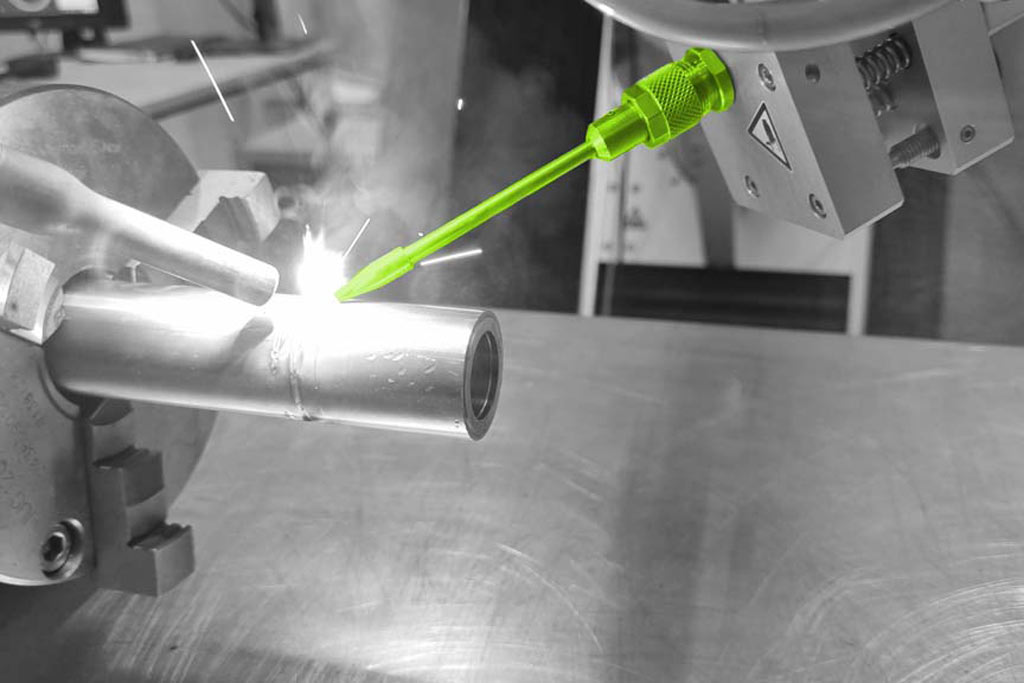

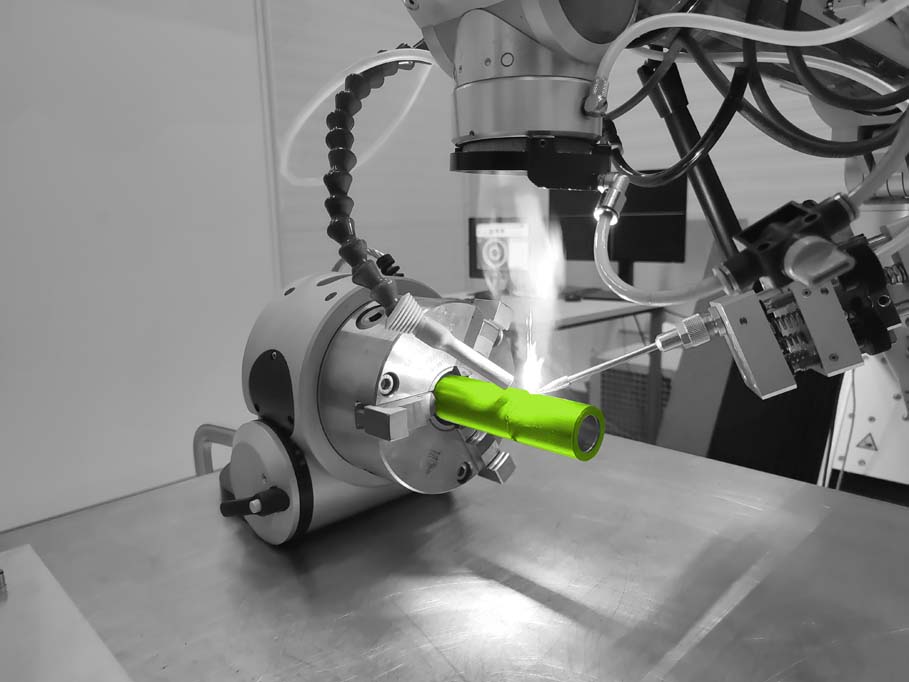

Laser processing

Laser welding, -cutting, -drilling, laser cladding

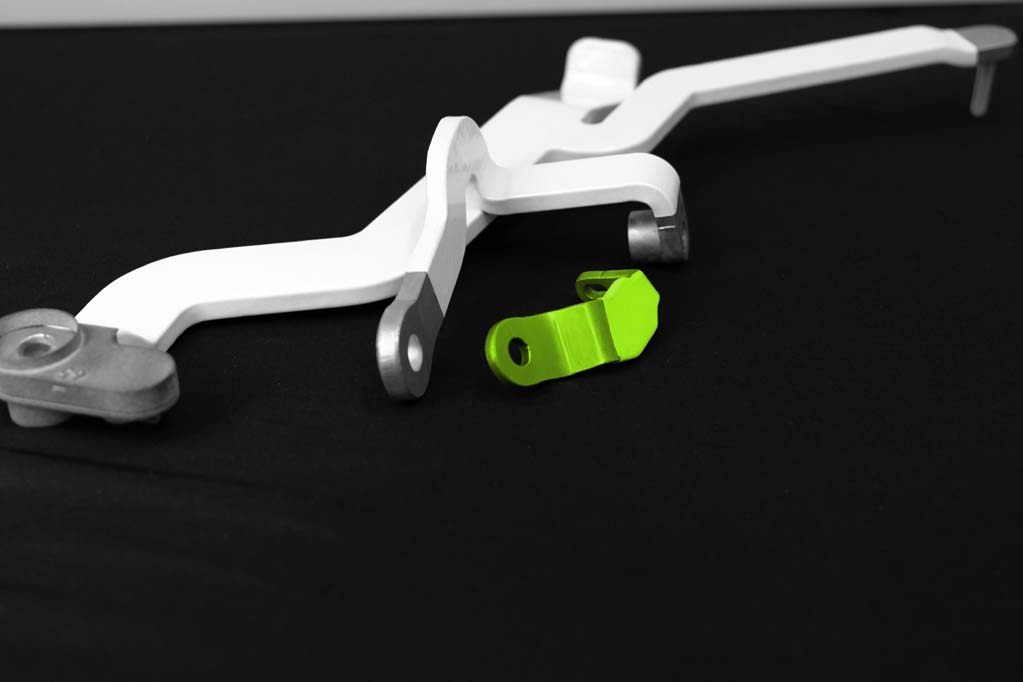

Additive manufacturing

Additive manufacturing of plastic

3D-printing polyamide 12

maximum 400x400x300mm

more materials available on request

Additive manufacturing of metal

3D-printing Aluminium, Titan, Inconel and stainless steel

maximum 250x250x300mm

on request larger dimensions possible and more materials available

Service

CAM programming

providing CAM/CAD-solution

Engineering

Solving problems and realizing ideas

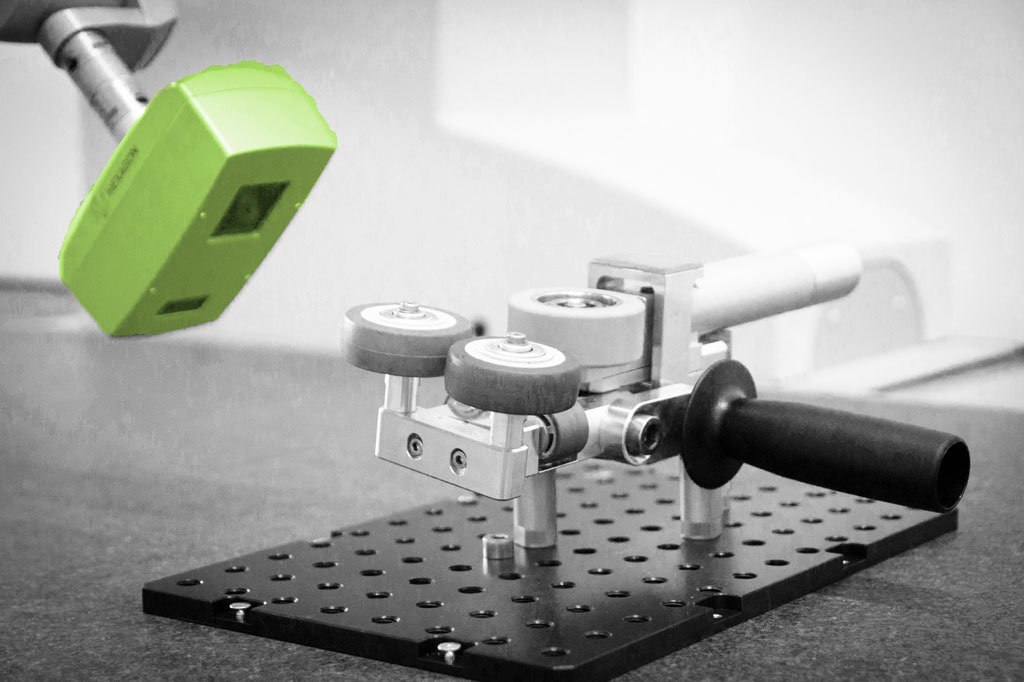

Scan & Reverse Engineering

Scan & Reverse Engineering

optical scanning and measurements 20 µm

tactile scanning and measurements 1,4 µm

Fixture construction and completion

Fixture construction

Manufacturing including mechanical and electrical components

Completion

Surface treatment, metal sheet manufacturing, cuts (water jet, laser cut), standard parts, welded moduls, assembling

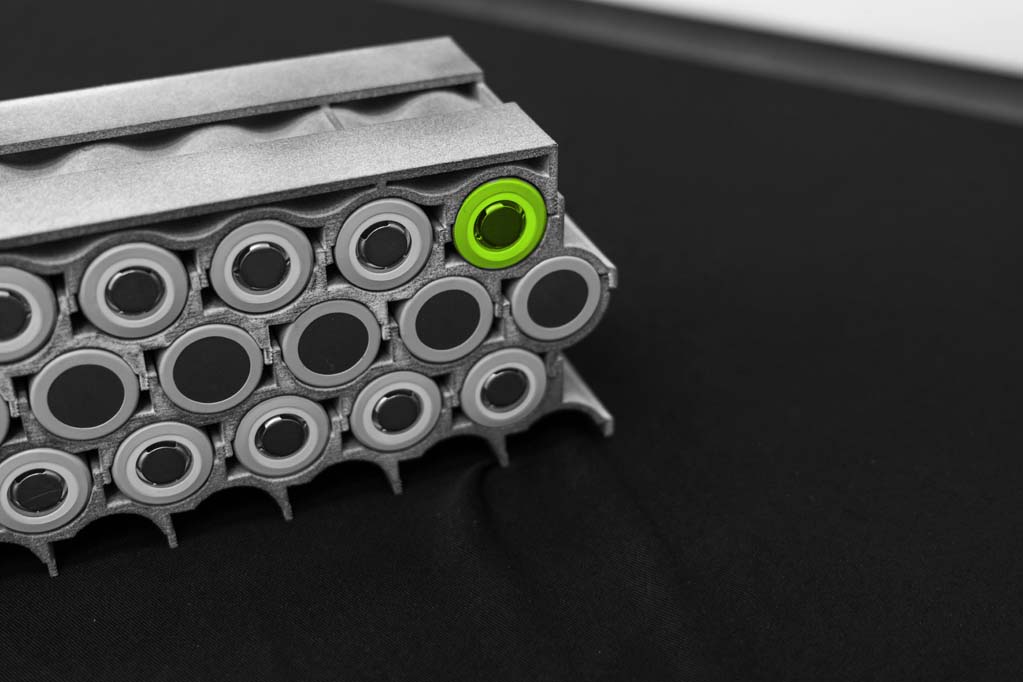

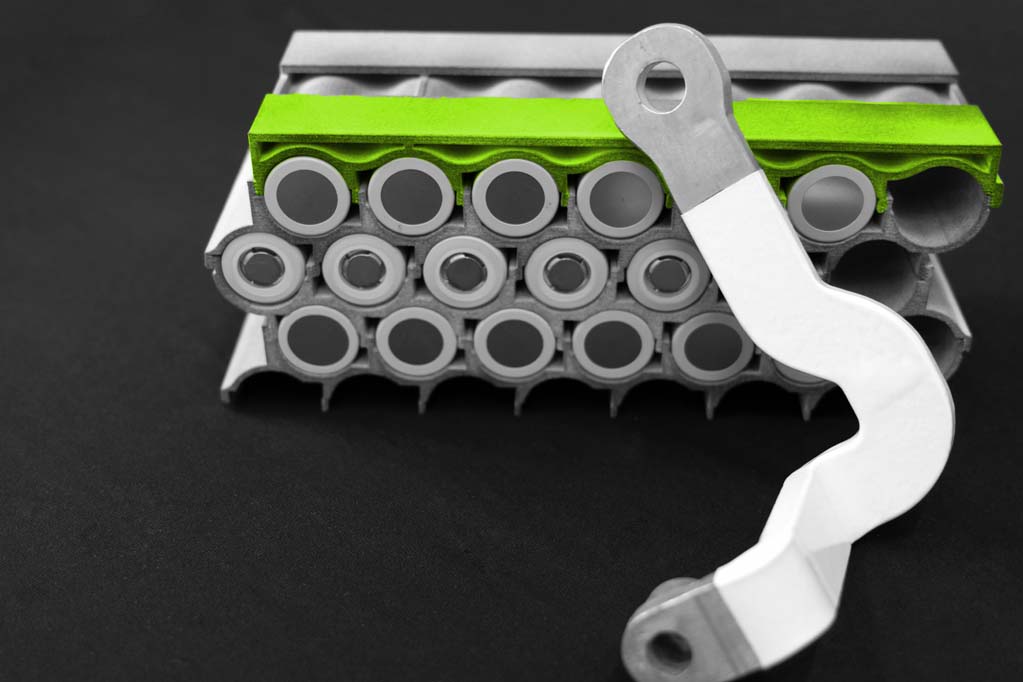

Battery Production

Module design

Design of cells (round, prismatic, pouch) into a module In-house development of a module system, safety management, recycling strategy

Fixture construction

Cell tab cutting for pouch cells, bending device for pouch cells, stacking devices (all cell types), welding device, manipulation devices, device for cell production

Production of HV components

Busbar, coating, insulation, heat sink, cable production

Prototype systems

Cell-to-pack systems, stacking systems, welding systems, bending systems, handling systems, punching systems – design and production included

Structure analysis

Testing and series readiness testing of module systems, cost- and time-efficient development of pre-series and variants, including analyses up to SOP (start of production)

Cell-to-module production

In-house production of the module

Module-to-pack

In-house production including completion

AUTOMATION

Automation

Structural analyses, robot programming

SPS programming

SPS programming